I-SV Thermal Conductive Two Component 1:1 electronic potting compound I-Sealant ye-Junction Box

Incazelo Yomkhiqizo

IZICI

1. I-viscosity ephansi, i-fluidity enhle, ukuchithwa kwe-bubble okusheshayo.

2. I-insulation kagesi enhle kakhulu kanye nokushisa ukushisa.

3. Kungaba ibhodwe elijulile ngaphandle kokukhiqizwa kwezinto eziphansi zamangqamuzana ngesikhathi sokuphulukiswa, kunokuncipha okuphansi kakhulu nokunamathela okuhle kakhulu ezingxenyeni.

UKUPAKASHA

A:B =1:1

Ingxenye: 25KG

Ingxenye B: 25 KG

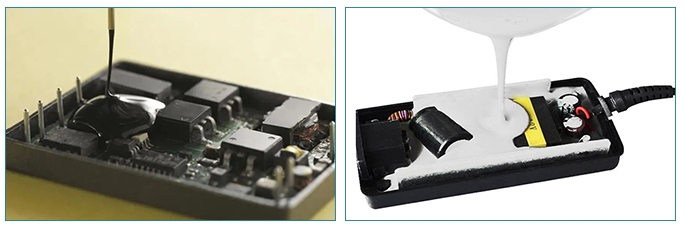

UKUSETSHENZISWA OKUYISISEKO

1. Ukubhoda kanye nokungangeni kwamanzi kumshayeli we-LED, ama-ballast, nezinzwa zokupaka ezihlehlayo.

2. I-insulation, conduction thermal, umswakama-proofing, kanye nemisebenzi yokulungisa ezinye izingxenye ze-electronic

IZIMPAHLA EZIJWAYELEKILE

Lawa manani awahloselwe ukusetshenziswa ekulungiseleleni imininingwane

| IMPAHLA | A | B | |

| Ngaphambi Kwengxube | Ukubukeka | Emhlophe | Mnyama |

| (25℃,65%RH) | I-Viscosity | 2500±500 | 2500±500 |

| Ukuminyana (25℃, g/cm³) | 1.6±0.05 | 1.6±0.05 | |

| Ngemva Kokuxutshwa | I-Proportion Ratio (Ngesisindo) | 1 | 1 |

| (25℃,65%RH) | Umbala | Okumpunga | |

| I-Viscosity | 2500 ~ 3500 | ||

| Isikhathi sokusebenza (imizuzu) | 40-60 | ||

| Isikhathi Sokwelapha (H, 25℃) | 3~4 | ||

| Isikhathi Sokwelapha (H, 80℃) | 10~15 | ||

| Ngemva Kokuhlinzwa | Ukuqina (Shore A) | 55±5 | |

| (25℃,65%RH) | Amandla Okuqina (Mpa) | ≥1.0 | |

| I-Thermal Conductivity (W/m·k) | ≥0.6~0.8 | ||

| Amandla e-Dielectric (KV/mm) | ≥14 | ||

| I-Dielectric Constant (1.2MHz) | 2.8~3.3 | ||

| Ukungazweli Ivolumu (Ω·cm) | ≥1.0×1015 | ||

| I-Coefficient Of Linear Expansion (m/m·k) | ≤2.2×10-4 | ||

| Izinga Lokushisa Lokusebenza (℃) | - 40 ~ 100 | ||

Bhala umyalezo wakho lapha futhi usithumelele wona